Thermography

Drone thermography

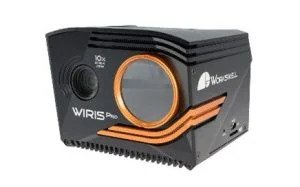

Superior Quality and Stabilization Without Compromise

The use of thermal imaging cameras combined with UAV drones is now a key for all industry experts involved in the inspection of PV fields, High Voltage Power Lines, Oil and Gas Pipelines, Buildings and structures in general.

The latest generation thermal imaging cameras combine high-resolution radiometric thermal sensors (up to 1266 x 1010pixels) with 16mp RGB visible sensors with up to 30x optical zoom. These two sensors combined with the rich set of remote control interfaces and georeferenced data via the drone’s GPS enable the creation of high-precision heat maps using available software, including in the Cloud.

|

|

Table Header  |

|

|

|---|---|---|---|---|

|

Model |

Flir Vue Pro R 336-640 |

Workswell Wiris Pro |

Workswell Wiris Enterprise |

Micasense Altum-PT |

|

Daylight Sensor |

N/A |

2.13MP-FullHD 1080p |

16MP-4K:3840*2160 |

5.1 MP |

|

Optical Zoom |

N/A |

10x, F3.8,f~88.4mm |

10x, F3.8,f~88.4mm |

|

|

Thermal Sensor |

640*480p - 9hz |

640*480p(1266*1010) - 30hz |

1266*1010p - 30hz |

320*256 - 30hz |

|

Digital Zoom |

4x |

14x |

12x |

|

|

Thermal band |

|

7.5-13.5um |

7.5-13.5um |

7.5-13.5um |

|

Other Sensor |

|

|

30X FullHD Zoom |

3.2MP: Blue 475(32), |

|

Multiview |

|

✓ |

✓ |

|

|

GPS Geotag |

Mavlink |

Mavlink-Direct |

Mavlink-Direct |

Mavlink-Direct |

|

Quick-Mount |

✓ |

✓ |

✓ |

✓ |

|

Video Out |

A/V |

HDMI-Ethernet |

A/V - HDMI |

WiFi |

|

Control |

PWM,Mavlink |

PWM,Mavlink,Ethernet,Can |

PWM,Mavlink |

PWM,Sbus,UART,TCP |

|

Weight |

113g |

430g |

680g |

460g |

|

Dimension |

57*44*45 mm |

83*85*68 mm |

77*107*102 mm |

89*70*110 mm |

|

|

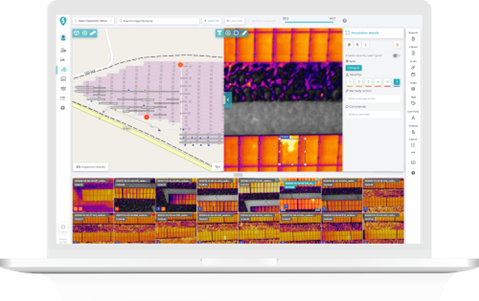

Photovoltaic

The use of thermal imaging cameras installed on drones provides a quick, inexpensive, and reliable method of inspecting solar panels in large-scale installations. These radiometric cameras designed for use with Unmanned Aerial Vehicles (UAV) drones represents a major breakthrough in thermography.

Often, defects in photovoltaic panels cause so-called “hot spots” to occur. These “hot spots” indicate electron recombination that can create holes in solar cells. During this process, a considerable amount of energy is released and radiates into space in the form of heat. These problem areas can heat up to very high temperatures; in fact, the difference between a good cell and a defective one can be more than 50° C. This heat can cause irreversible damage to both the defective cell and the entire panel.

Radiometric drone cameras are an ideal solution the search for anomalies and hotspots on PV systems. HotSpots are clearly visible in thermal images, and with the software provided, they can be mapped and georeferenced to allow fsacilitated location on site and have technicians intervene to Fix or replace panels. Using a drone to inspect photovoltaic panels makes it possible to scan up to 2mw now and save so much time compared to traditional methods with manual inspection from the ground, plus the software available today makes it possible to reconstruct a faithful map of the plant in just a few steps and create accurate and fast reports

Pipeline Thermal Inspection

Aerial drone thermographic inspection of pipes and ducts is one of the most usual applications of UAVs due to their great flying capacity it is possible to scan kilometers of ducts by detecting temperatures that are in contrast to the ambient air temperature. Thermographic systems exploit this fact to identify and detect leaks and defects in pipe insulation. In some cases, it is even possible to identify and locate leaks in underground pipelines with aerial inspections.

Pipelines transport a wide variety of substances, including water (hot water pipes, water pipes), steam (steam lines), petroleum products (oil or gas), and a variety of chemicals used in food production, agriculture, power plants Mining, etc. In many cases, pipelines are used not only to transport the substance in question, but to transfer the heat energy associated with the fluid being transferred. This is why thermal insulation of the pipeline, and any potential pressure loss within it, is so crucial. The entire transportation system must be perfectly sealed, especially leaks not only lead to loss of energy and money, but can also create major environmental problems.

Our thermographic monitoring and inspection systems include two cameras: a visible spectrum camera that enhances inspection of visible pipeline defects and a thermal imaging camera that detects hidden defects. Control software allows remote switching of camera modes, shooting of radiometric videos, and acquisition of static images in both visible and infrared spectra. An operator can then see a video feed from the drone in real time. They can also analyze recorded videos or later saved images to identify damaged areas.

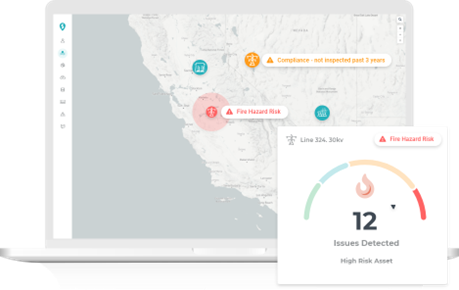

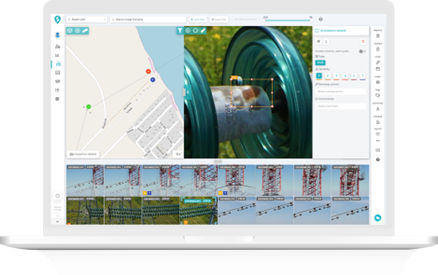

Power Line Inspection

Our platform uses automation and machine learning to process and manage your drone-acquired geospatial data.

Over time, your historical inspection data will become the ever-performing engine for predictive maintenance.

Visual data analysis, powered by artificial intelligence AI inspection annotates faults in your images quickly and accurately.

Cloud software for analysis and reporting

To get the best possible results, you need the best solar inspection software combined with the best thermal inspection platforms with Drone

Our cloud-based platform keeps your data easily accessible and secure, and allows you to share inspection results with everyone in the field

Welcome to the Future of Drone Inspection

Our platform uses automation and machine learning to process and manage your drone-acquired geospatial data.

Over time, your historical inspection data will become the ever-performing engine for predictive maintenance.

Visual data analysis, powered by artificial intelligence AI inspection annotates faults in your images quickly and accurately.

We unlock the potential of your data.

Scopito is more than secure data storage. We work with AI-based error detection, “digital twin” technology, historical data, and real-time risk assessment to keep your team informed.

In short, Scopito turns your raw data into valuable geospatial information

Attention to workflows.

Simple and intuitive interface, data always available, access for every team member, We are always looking for ways to introduce smarter automation into workflows, thus enabling maximum simplification for all drone visual inspection work.

The result is detailed analysis and timely reports ready for the maintenance team.

Talk to one of our Experts

DroneBase provides you with an Expert Advisor

Able to recommend the most appropriate product for your needs

And answer all your questions.

Call us NOW!

+39.0541.1790411

Request information

Please enter your details below, our consultant will

will contact back as soon as possible and provide you with all the details!